Susanne Pierce Maddux

MDes Spring 2022

Project Aer, is an innovative material-forward design approach solving for sustainable and affordable home air filtration. Project Aer explores theinherent values, versatility and beauty of the material active charcoal by using it to replace plastic parts and as act as a filtration mechanism.

Abstract

Global air pollution is a growing health concern. The health risks of chronic exposure to air pollutants are many and include respiratory disease, emphysema, bronchitis, asthma cardiovascular disease, and cancer. The current model of eco-unfriendly plastic enclosure filter systems paired with the costly price and maintenance of home filtration is a barrier to clean air for lower-income households. Because of these downsides, the most widely used design pattern for home air filtration systems fails to address the urgent problem of improving indoor air quality in an affordable and eco-friendly way.

In response, this project, Aer, proposes a new approach that employs innovative and eco-friendly manufacturing and filtrations methods, creating a more accessible and affordable design solution. The project proceeds through a well-established industrial design methodology including research, exploration, concept design, iteration, refinement, and product development.

In that charcoal is a vital component in improving air quality, this material is explored not only for its functionality as a filtration medium capable of removing VOCs, but also foregrounded strongly in the design of the housing, thereby highlighting the prominence of this castable and moldable bioplastic, and also removing the need for traditional plastics from the product life-cycle ecosystem.

Method

Project Aer proceeds through a well-established industrial design methodology of research, exploration, concept design, iteration, refinement, and product development.

In my work I investigate and research existing methods of home filtration of fine particulate matter and VOCs. Carbon air filters remove pollutants from the air with a process known as adsorption. During the activated carbon adsorption process, compounds in the contaminated air react with the carbon to stick to the surface area, effectively removing these contaminants from the air. Another important investigations are the materiality of charcoal as a bioplastic within applicable manufacturing methods for a consumer home product as well as existing methods of using charcoal as a medium in design applications.

I limited my charcoal bioplastic recipes to the ingredients of charcoal, water, vegetable glycerin, and gelatin all-natural ingredients. I referenced the open-source formulas published by the group FabLab and experimented with my own formulas working with variations to create delicate lacelike bowls inside silicon castings and solid castings that could be formed.

I experimented with a variation of charcoal bioplastic recipes not only for manufacturing capabilities in moldings but for final color, material, finish the evaluation, and potential filtration effectiveness. In my process work, I explored molding the charcoal bioplastics. It was while working with these moldings that I realized the possibility of using the bioplastic as a material to replace plastic as a housing material in a consumer air filter

Final Design

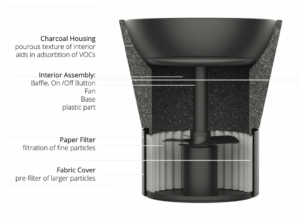

Aer’s consumer product air filtration solution is an elegant design employing a duality of material and function combined with a form factor communicating iconic simplicity The final design delivers an ecologically, material-first solution consisting of three primary components, a bioplastic charcoal housing to filter the VOCs, and a paper filter base to filter the fine particulate matter (both of which are compostable biomaterial).

Aer’s innovative design methodology and material implementation are central to Aer’s successful design. Where the charcoal bioplastic acts as both filter and housing, facilitating simplicity and duality and the opportunity for the creation of an elegant iconic design that celebrates the value of the materiality of charcoal. In addition, unlike the millions of air filters that end up in landfills every year, Aer’s compostable parts will decompose in the soil creating a truly sustainable product solution.

Designing with the bioplastic material charcoal I found it important to the design story to integrate the inherent beauty and versatility of charcoal into the visual and functional CMF (Color, Material, and Finish) experience of Aer. Bringing into alignment the narrative of the material as a filtration device and as a product housing, strengthening the connection through design.

Full listing